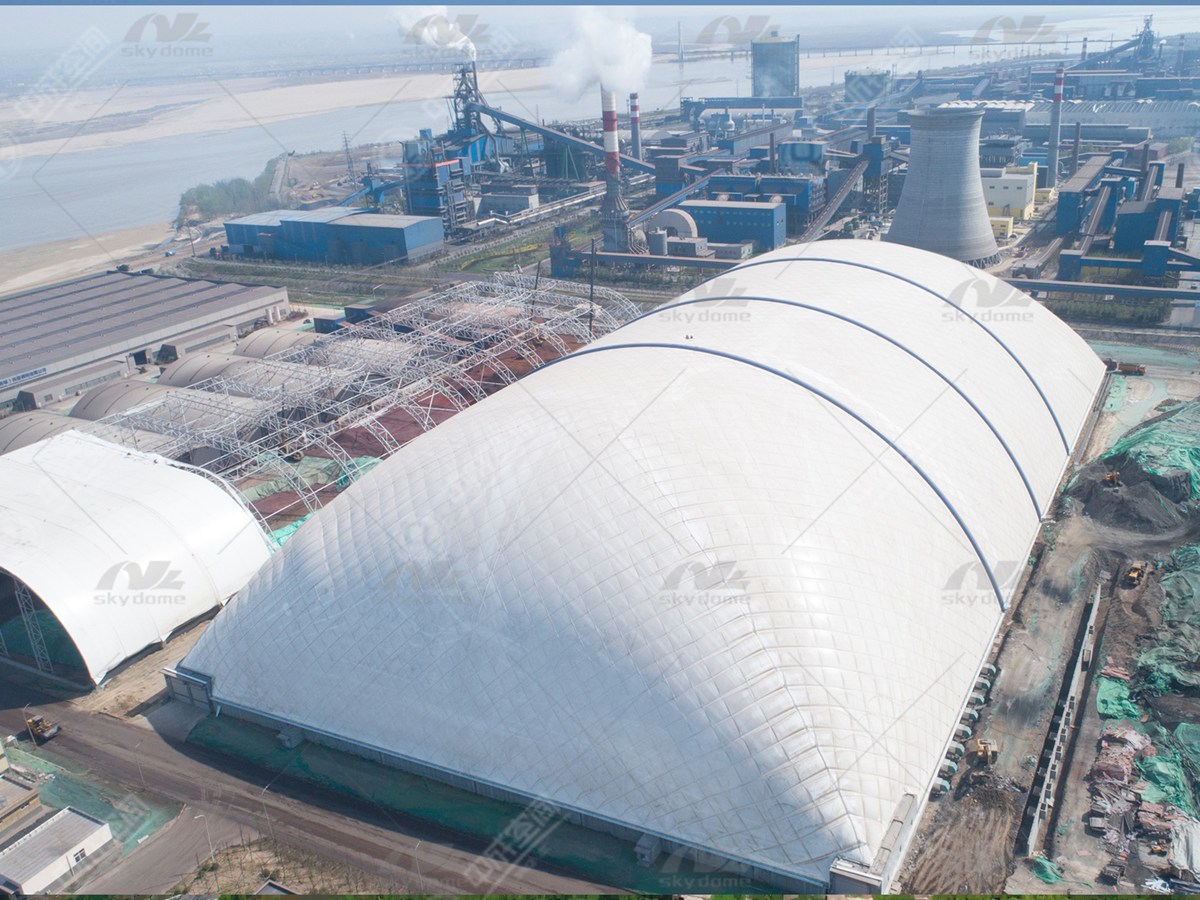

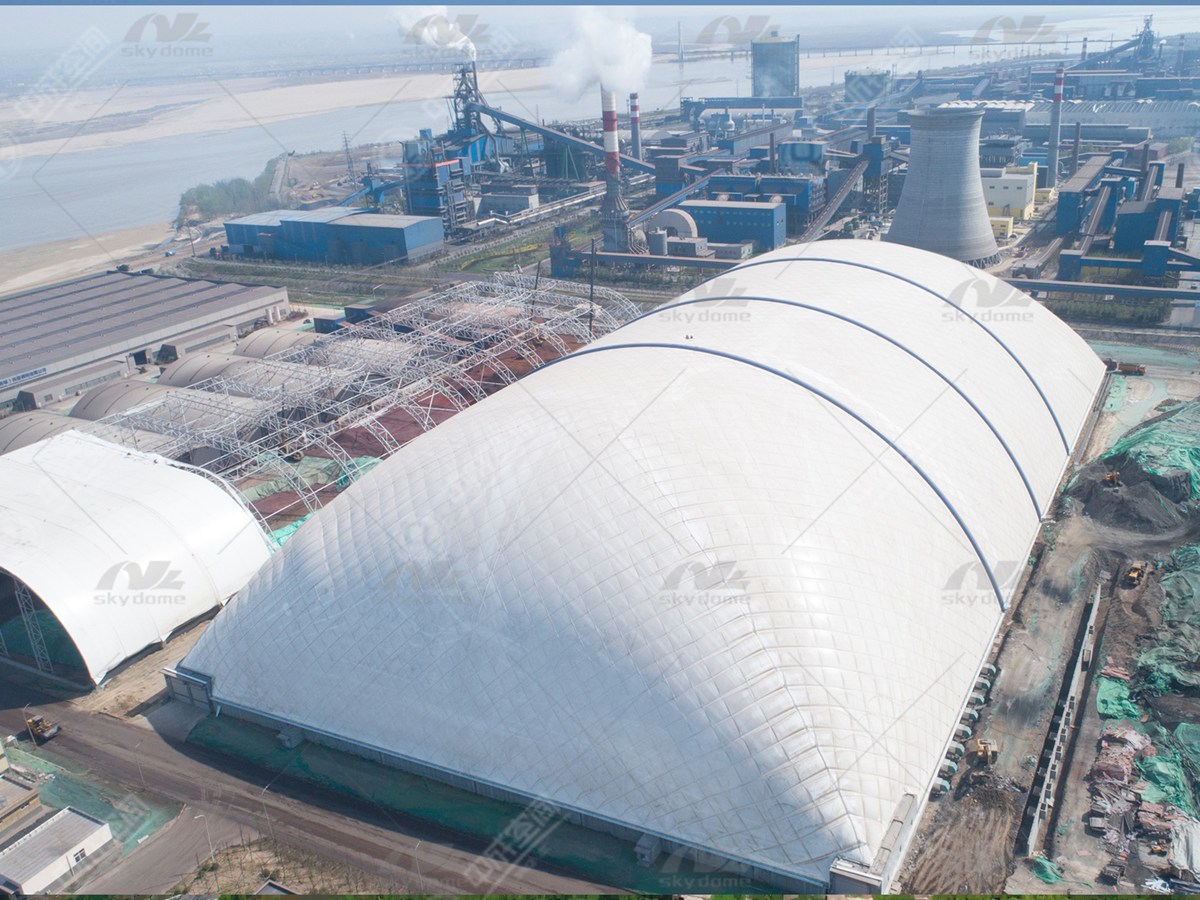

Understanding Air Domes and Their Main Body Fabric Needs

Air domes are increasingly popular for their versatility and durability in various applications. The main body of an air dome is crucial as it directly impacts the structure’s integrity and function. Selecting the right fabric for this component is essential for ensuring the air dome’s longevity and performance. The fabric must withstand environmental stresses, maintain air pressure, and provide a reliable barrier against external elements.

When choosing fabric for the main body of an air dome, it’s important to consider the specific requirements of the intended use. For instance, air domes used in agricultural applications may need fabrics that resist UV degradation and have good thermal insulation properties. Conversely, air domes designed for recreational use might prioritize comfort and aesthetic qualities. Understanding these nuances is key to making an informed fabric choice that aligns with the air dome’s purpose and expected conditions.

Key Factors to Consider When Selecting Fabric

Several critical factors should guide your selection of fabric for the main body of an air dome. These include durability, breathability, insulation properties, and resistance to environmental factors such as UV rays and chemicals. Each of these aspects plays a vital role in determining how well the air dome will perform over time.

Durability is paramount, especially for air domes exposed to harsh conditions. Fabrics that can withstand wear and tear without compromising their structural integrity are essential. Breathability is another important factor, particularly in applications where air circulation is necessary. Fabrics that allow for adequate airflow help maintain the desired internal conditions within the dome.

Insulation properties of the fabric are also crucial, particularly in extreme weather conditions. Fabrics with good thermal insulation can help maintain stable internal temperatures, regardless of external fluctuations. Additionally, resistance to environmental factors like UV rays and chemicals is critical for ensuring the fabric’s longevity and maintaining the air dome’s functionality over time.

Evaluating Fabric Durability and Strength

Evaluating the durability and strength of fabric is a critical step in selecting the right material for the main body of an air dome. Durability refers to the fabric’s ability to withstand wear, pressure, and environmental conditions without degrading. Strength, on the other hand, is about the fabric’s ability to resist tearing and stretching under load. Both these factors are crucial for the structural integrity and longevity of the air dome.

One of the primary considerations is the fabric’s resistance to punctures and tears. Air domes are often subjected to various stresses and strains, and the fabric must be robust enough to resist damage. Testing methods such as the ASTM D751 standard can help evaluate a fabric’s tear strength, which is essential for ensuring the air dome can withstand the rigors of its environment.

Another important aspect is the fabric’s tensile strength, which determines how much force the material can endure before breaking. This is particularly important for air domes that need to maintain internal pressure and resist external forces. Tensile strength testing, according to standards like ASTM D5034 for woven fabrics, can provide valuable insights into a material’s suitability for air dome applications.

Moreover, the fabric’s resistance to environmental factors such as UV radiation, moisture, and temperature extremes is crucial. Fabrics that are treated or inherently possess UV resistance, for instance, will have a longer lifespan when exposed to sunlight. Similarly, materials with moisture-wicking properties can help prevent mold and mildew growth, which can compromise the air dome’s integrity.

In summary, assessing the durability and strength of fabric involves a comprehensive evaluation of its performance under various conditions. This includes testing for puncture and tear resistance, tensile strength, and resilience to environmental factors. Choosing a fabric that excels in these areas is essential for ensuring the air dome’s durability and functionality over its intended lifespan.

Understanding Breathability and Insulation Properties

Breathability and insulation are two critical properties that significantly influence the performance and comfort of an air dome. Breathability refers to the fabric’s ability to allow air and moisture to pass through it. This property is crucial for preventing condensation and maintaining a comfortable internal environment. On the other hand, insulation refers to the fabric’s ability to resist the transfer of heat. Good insulation is essential for maintaining stable internal temperatures, regardless of external weather conditions.

The breathability of a fabric is often determined by its construction and the materials used. For instance, fabrics with a tighter weave or made from materials with low moisture absorption tend to be less breathable. Conversely, fabrics that are loosely woven or made from natural fibers like cotton or wool often have higher breathability. Testing methods such as the ASTM E96 standard for water vapor transmission can provide insights into a fabric’s breathability.

Insulation properties are equally important and are determined by the fabric’s thickness, density, and material composition. Thicker and denser fabrics generally offer better insulation, as they create more air pockets that can trap heat. Materials like polyester and nylon are known for their excellent insulation properties, making them suitable for air domes in colder climates. Insulation testing methods, such as the ASTM C518 standard for steady-state thermal transmission properties, can help evaluate a fabric’s insulation performance.

In summary, understanding the breathability and insulation properties of fabric is crucial for selecting the right material for an air dome. These properties significantly impact the internal environment of the dome, influencing comfort levels and the dome’s overall performance. Testing and evaluating these properties according to industry standards is essential for making an informed fabric choice.

Evaluating Resistance to Environmental Factors

Evaluating a fabric’s resistance to environmental factors is a critical step in selecting the right material for the main body of an air dome. Environmental factors such as UV radiation, moisture, temperature extremes, and chemical exposure can significantly impact a fabric’s durability and performance. Therefore, choosing a material that can withstand these conditions is essential for ensuring the air dome’s longevity and functionality.

UV resistance is a key consideration, especially for air domes exposed to sunlight for extended periods. Fabrics treated with UV inhibitors or those made from inherently UV-resistant materials like certain types of polyester or acrylic are ideal for such applications. These materials are less likely to degrade or lose their structural integrity when exposed to UV radiation over time.

Moisture resistance is another critical factor, particularly for air domes used in humid or wet environments. Fabrics with moisture-wicking properties can help prevent condensation and mold growth, which can compromise the air dome’s integrity. Materials like Gore-Tex or other waterproof-breathable fabrics are excellent choices for applications where moisture resistance is paramount.

Additionally, evaluating a fabric’s resistance to temperature extremes is crucial. Fabrics that can maintain their performance in both high and low temperatures are essential for air domes used in varying climatic conditions. Materials like silicone-coated fabrics or high-temperature-resistant PVC are suitable for applications requiring resilience to temperature fluctuations.

Chemical resistance is also an important consideration, especially for air domes used in industrial or agricultural settings. Fabrics that can withstand exposure to chemicals without degrading are essential for maintaining the air dome’s functionality in such environments. Materials like chemical-resistant PVC or rubberized fabrics are ideal for these applications.

In summary, evaluating a fabric’s resistance to environmental factors involves a comprehensive assessment of its performance under various conditions. This includes testing for UV resistance, moisture resistance, temperature resilience, and chemical resistance. Choosing a fabric that excels in these areas is essential for ensuring the air dome’s durability and functionality over its intended lifespan.