Inflatable domes, often referred to as air domes, have become an increasingly popular solution in sports, events, warehousing, and temporary or semi-permanent facilities. Their versatility, relatively quick installation, and cost-effectiveness make them a strong alternative to traditional construction. However, for businesses, organizations, and individuals considering an air dome, one common question arises: How long do inflatable domes last?

The answer is not straightforward, as the lifespan of an inflatable dome depends on several factors, including material quality, maintenance practices, environmental conditions, and usage intensity. This article explores these aspects in detail to give you a clear picture of what to expect when investing in an air dome.

1. Average Lifespan of an Air Dome

On average, a well-manufactured and properly maintained inflatable dome can last between 10 to 20 years. The exact lifespan depends on the quality of the materials, the design of the dome, and how consistently it is maintained. Domes constructed with advanced fabrics, reinforced membranes, and durable anchoring systems are more likely to last closer to two decades, while those exposed to extreme climates or neglected in terms of upkeep may experience a shorter life span.

It’s also important to note that different components of an air dome age at different rates:

Fabric/Membrane: Usually lasts 10–15 years, with longevity influenced by UV exposure, protective coatings, and overall wear. Regular cleaning and applying protective treatments can help preserve its strength.

Air Handling System (Fans and Blowers): Typically has a service life of 8–12 years. While the system as a whole can function for over a decade, individual components like motors or filters may need servicing or replacement earlier.

Anchoring and Support Systems: With proper installation, these parts can last 15 years or more, as they endure less wear compared to the fabric or mechanical systems.

In practice, while the dome as a complete structure may serve reliably for up to two decades, some parts will require timely replacement or refurbishment. This proactive approach not only extends the dome’s usability but also ensures safety and consistent performance throughout its lifecycle.

2. Factors That Influence Lifespan

a Material Quality

The primary determinant of how long an inflatable dome lasts is the material it is made from. Modern domes use PVC-coated polyester or other high-strength synthetic fabrics. Additional coatings, such as UV inhibitors and fire-retardant treatments, significantly enhance performance and longevity. Cheaper fabrics may degrade within a few years, while premium-grade membranes resist tearing, fading, and weather-related damage much longer.

b Climate and Environmental Exposure

Weather plays a critical role in durability:

Cold Climates: Domes in snowy areas must be designed to handle snow load. Membrane strength and air pressure systems are critical to prevent collapse.

Hot Climates: Constant sun exposure accelerates UV degradation of fabric. UV-resistant coatings help mitigate this.

Windy or Storm-Prone Areas: Strong anchoring and reinforced designs are essential for longevity.

c Usage Frequency

Domes used year-round generally experience more wear and tear than seasonal domes that are inflated and deflated according to need. However, frequent installation and takedown cycles can also create stress on seams and anchoring points.

d Maintenance Practices

Regular cleaning, inspection, and servicing are vital. Neglecting small tears, failing to monitor air pressure, or ignoring fan system warnings can shorten the dome’s usable life dramatically. Properly maintained domes almost always outlast neglected ones by several years.

3. Signs of Aging in Inflatable Domes

Even the best air domes eventually show signs of aging. Owners and operators should monitor for the following:

Fabric Discoloration or Fading: A natural result of UV exposure, though it does not always indicate structural weakness.

Micro-Cracks or Tears: Small surface cracks can spread if not promptly repaired.

Air Leakage: A drop in internal pressure or increased blower usage may signal leaks or membrane deterioration.

Fan or Blower Efficiency Decline: Older systems may run louder or require more energy.

Stitching or Seam Wear: Seams often experience the greatest stress and should be regularly checked.

Identifying and addressing these signs early ensures the dome remains safe and operational while extending its useful life.

4. How to Extend the Lifespan of an Air Dome

a Routine Cleaning

Dust, dirt, bird droppings, and pollution particles can degrade dome surfaces. Cleaning the membrane periodically with non-abrasive solutions prevents buildup and helps coatings last longer.

b Preventive Repairs

Promptly patching small tears or weak seams can prevent larger, costlier damage. Professional inspection teams can identify potential weaknesses before they become serious.

c Equipment Maintenance

Fans, blowers, and control systems are the “heartbeat” of an air dome. Keeping motors lubricated, replacing filters, and testing backup power sources ensures consistent performance and protects the dome from collapse during power failures.

d Seasonal Adjustments

Operators in climates with harsh winters may choose to reinforce structures during snow season or lower pressure slightly in hot summers to reduce fabric stress.

e Professional Inspections

Annual or biannual inspections by the dome manufacturer or certified technicians can uncover hidden issues. A small investment in maintenance can add several years to the dome’s life.

5. Comparing Air Domes to Traditional Structures

While air domes may not last as long as permanent steel or concrete buildings (which can exceed 50 years), their shorter lifespan is balanced by:

Lower upfront cost compared to traditional construction.

Flexibility and portability—domes can be relocated if needed.

Fast installation—a dome can often be installed within weeks, versus months or years for conventional buildings.

Energy efficiency—modern domes are designed with insulation layers to reduce heating and cooling costs.

For many organizations, particularly sports facilities, schools, event planners, and logistics operators, these advantages outweigh the shorter lifespan.

6. Case Examples of Longevity

Sports Domes in North America: Many athletic facilities report dome lifespans of 12–18 years with consistent maintenance. Replacement often involves fabric upgrades while reusing existing anchors and fans.

Industrial Storage Domes in Europe: These structures have been in service for 15+ years, with some only requiring partial fabric replacement.

Event Domes Worldwide: Temporary domes used seasonally often last longer than expected since they are not exposed year-round, sometimes reaching 20 years.

These examples show that with proper planning and care, inflatable domes provide a reliable long-term solution.

7. Cost vs. Longevity Considerations

When evaluating air domes, it’s important to weigh lifespan against overall value:

A dome lasting 15 years with proper care may still be more cost-effective than building a permanent facility upfront.

Replacement of certain components (like fans or sections of fabric) can refresh a dome at a fraction of the cost of full replacement.

Modern innovations, including double-membrane domes with insulation layers, are pushing lifespans even further.

This makes air domes an appealing option for organizations seeking both flexibility and long-term durability.

Conclusion

So, how long do inflatable domes last? With high-quality materials, professional installation, and consistent maintenance, air domes can remain functional for 10 to 20 years or more. While environmental conditions and usage intensity play major roles in longevity, proper care and periodic upgrades significantly extend their service life.

For anyone considering an investment in an air dome—whether for sports, warehousing, events, or temporary facilities—the key is to work with experienced manufacturers who understand the engineering and maintenance requirements involved.

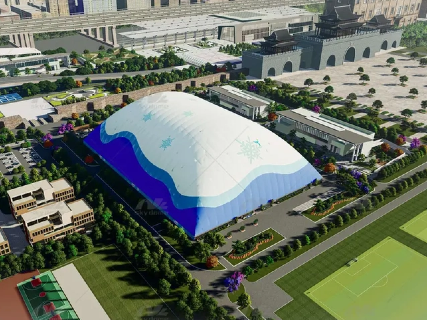

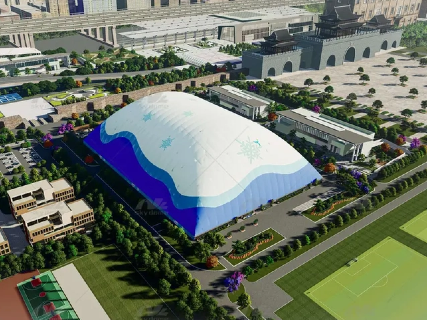

If you’re exploring options for durable, efficient, and customizable air dome solutions, we recommend reaching out to Sky dome Co., Ltd. The company specializes in designing and delivering reliable inflatable dome systems that balance longevity, safety, and functionality. Their expertise can help ensure your project is built to last.